How to Install Rvinyl Fender Wraps

If you want to restyle your bumpers and give them a fresh new look, vinyl

fender wraps are some of the best options you can choose. At Rvinyl, we carry

only the best fender wrap brands available today, ensuring you receive durable

vinyl wraps designed to last many years. We also stock fender wraps in various

colors and designs, so you can always trust us to supply you with the perfect

wrap for your creative vision. And if you're looking for some tips, we got you

covered. We asked Justin Pate of The Wrap Institute to create a video that

covers the process from start to finish. You will want to assemble the following

tools before beginning:

- Blade Cutter

- Squeegee

- Gloves

- Microfiber Towel

- Rapid Prep

- Masking Tape

- Monkey Strip

- Snitty

- Magnets

- Avery Dennison Flextreme

Step 1: Cleaning and Preparation

The first step is to clean, spray Rapid Prep on a highly absorbent microfiber

towel, take a tucking towel and place it inside the microfiber towel and go.

After all, the tight gaps start at one point on the front fender and do360-degree loop where from one point all the way around back to it. This could mean

opening up the hood to remove dust from the inside section there, as well as the

front door as a lot of dirt and oil can build up on this inside gap. So work

from top to bottom and be extra focused here. Once all the outside edges are

clean, then it's time to clean the main surface area. Spray Rapid Prep on the

microfiber hotel one more time and then wipe it down from top to bottom. Now,

with the cleaning process done, it's time to move on to the next stage, which is

masking tape. Once all the masking tape is set up the wrapping process can

begin.

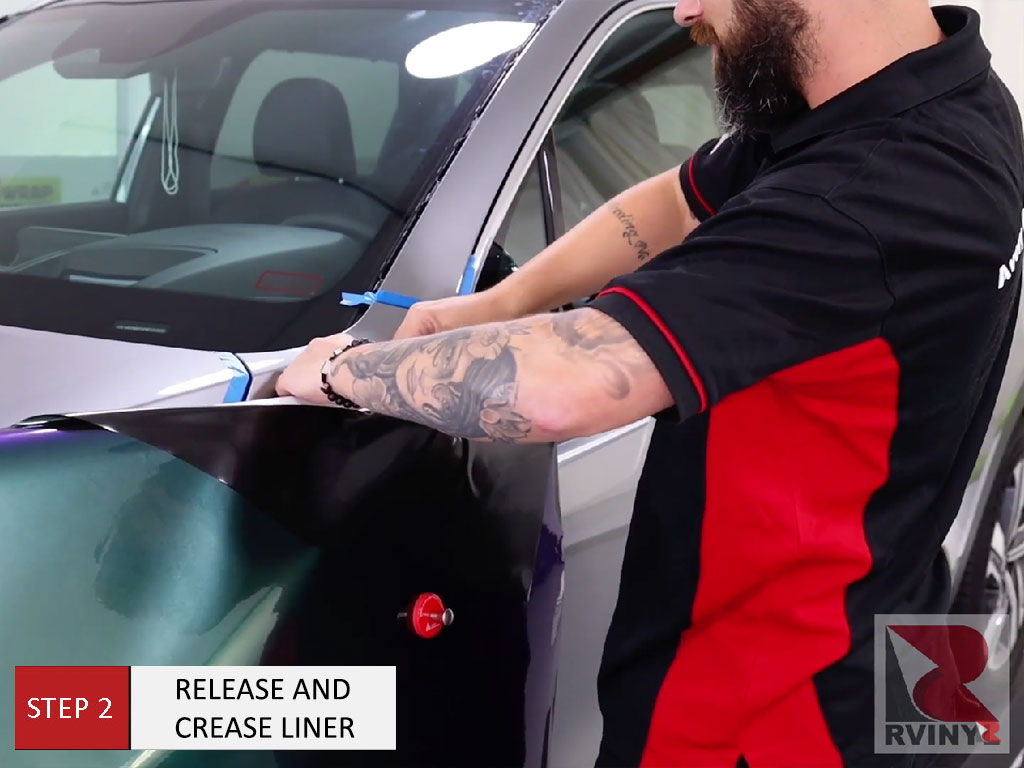

Step 2: Release and Crease Liner

Place the piece on the fender with magnets, then take a Snitty and cut the

material safely away. This means the knife won't touch the surface and there's

no damage to the vehicle. Now, with the material prepped and trimmed, it's time

to release the liner: here, starting at the top release at roughly six or seven

inches fold the material under, no need to cut it. Then once the material is

creased and laying flat, pick the material up and hook the upper corner. This

will lock it in place and, by starting at the corners of the top, this means

they'll be better quality - no tension. Lock it into the upper body line of the

fender then pulled the liner low and flat underneath the vinyl. This means

there's no dust coming onto the adhesive side, which will help keep a high-quality finish. Once the liner has been removed, the main section is time to

glass it out. This means creating no wrinkles on the film, picking up nice and

high and pull it along the body line nice and even so, pull from top and bottom.

And once it hits the body line with even tension, lay it flat and lock it in

with a thumb.

Step 3: Pull the Liner

Now release the rest of the liner and pull towards the corner by pulling

towards all the corner, the material will have a wrinkle-free state. Once it's

wrinkle-free always apply the recessed areas first. This is called the palm

technique, which was invented by the Wrap Institute by doing the palm technique.

This means there'll be no adhesive lines so the quality of the finish will be

great. So once the film is locked into this upper recessed area, now you can

come back and finish the corners with the Avery Dennison Flextreme, pick the

material up high and then hook the corner. This will mean the corners will be

extra flat and look like paint. So once the top section is finished, then it's

time to squeegee any remaining air out from underneath the film using a monkey

strip on a squeegee, then lock in the top edge.

Now the film can then be tucked

deep into the base using the hard side of the squeegee and a Flextreme. It is

very important to take the film as deep as you can. Always use a very sharp

blade and keep the angle of the blade at a 10-degree angle towards the surface.

This means it'll be held safely by the edge of the raised object and won't cut

the paint below it. Make sure you always cut towards yourself and never away.

Once all the excess film has been cut away, retract the blade and pull the

excess film away from the raised object and immediately tuck it in with the

talking tool with all the materials safely on the main surface of the front

fender.

Step 4: Use Heat to Relax Film

It's now time to cut away the excess film on the edges. Always go around with

the heat gun to relax the film on the edges, cut the corners first, and when

possible, always allow the blade to be guided along the edge on the opposite

side of the front fender. This will allow around one-quarter inch of film that

can then be wrapped around for full coverage so the color wraps around the

fender as well as for extra hold. Once that section has been applied work to on

another section. The tight gap between the front bumper and front fender should be

tucked in and the masking tape allows the film to slide safely deep into the

gap. Run the blade just in the middle of the gap, never cut directly on the

surface, then remove the excess film and immediately come back in and seal the

deal.

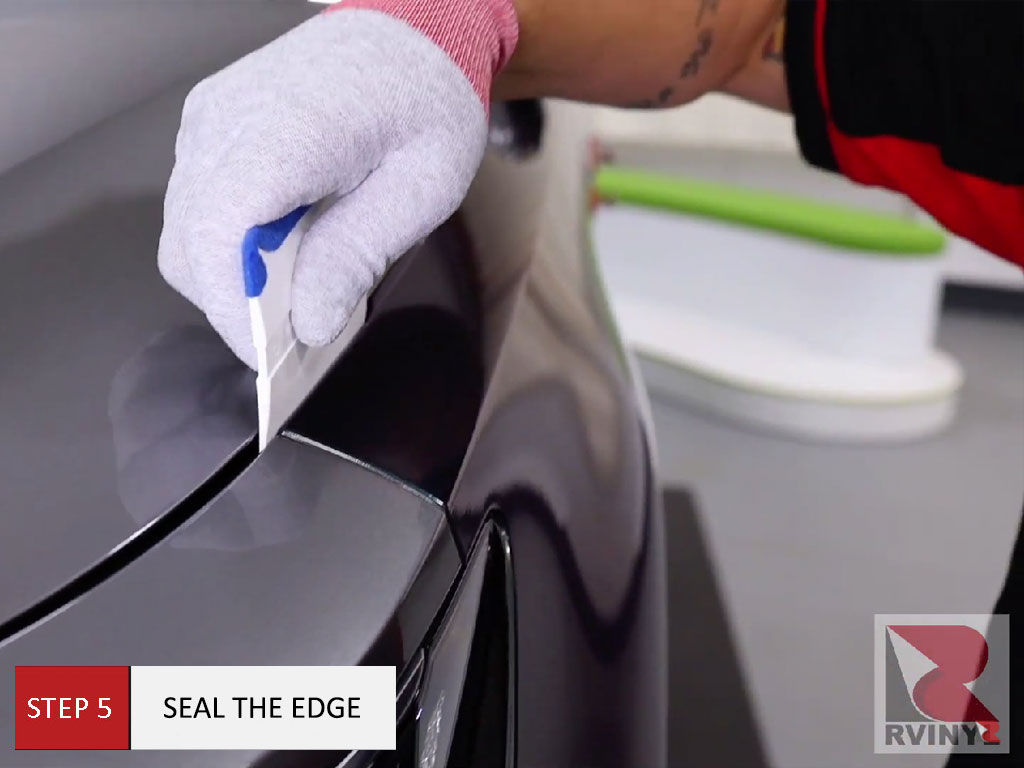

Step 5: Seal the Edge

Now we can move into the top section: here by cutting on the opposite side

alongside the hood that quarter of an inch of excess material is then tucked

into the gap for full coverage and held on a finger with an application glove, then

run a squeegee deep into the gap to seal the edge. Very straightforward.

Step 6: Finishing Touches

To finish, simply spray the surface and wipe it down with a microfiber towel

to remove any handprints and also double-check that all the edges are sealed.