Vinyl Film: What Are the All of the Types?

Thanks to the internet, we are all heir to an almost unprecedented amount of

information about vinyl films. These days, you don't have to be a sign shop

owner or in the creative department of a large company to have access to the

full array of adhesive vinyl films on the market. Still, knowing whether to

choose Avery™ SC950 Ultra Metallic versus ORACAL® 631 Cal film can be

almost impossible if you know nothing about the differences in the films. But,

wait, there's more. In addition to true vinyl films many brands offer polyester

films too which can make it even more confusing. Plus,

if you're a true beginner, you may not even know what you want to do wit the

film. In the following article, we'll look at the general types of vinyl film

out there and then break them down even further into specific applications.

There's More Than One Way to Bake a Cake

There a more than a few ways we could start but it might be best to start

off by differentiating between adhesive vinyl and heat-transfer vinyl (also

commonly referred to as HTV). Adhesive vinyl is by far the more common type and

is just that: a vinyl film with a sticky (adhesive) side and a non-adhesive,

colored face. Heat transfer vinyl, on the other hand, is a specialty vinyl that

may be used on fabrics and other materials to create designs and promotional products.

Generally sold in a roll or sheet form with a heat-activated adhesive backing so it can be cut, weeded, and placed on a substrate for heat application.

Because we only specialize in adhesive craft, sign and wrap films we won't be

discussing this type of film further but Siser HTV is one of the most well-known

and trusted brands if that's what you're looking for.

Cast versus Calendered Vinyl

The next major division of vinyl films is with regard to how they are

manufactured. This, in turn, tells you a lot about their suitability for various

applications and end uses, their durability and, of course, their cost. There

are currently two primary forms of mass production of vinyl films and they are

casting and calendering. We'll go into some detail below but, for a more

in-depth analysis, check out our article on the

differences between cast and calendered

vinyl

.

Cast Vinyl

Cast vinyl film is made through a process referred to as casting. In

other words, the material that will eventually become a sheet or roll of cast

vinyl starts out as a mixture that resembles a thick, viscous plastic paint.

Plasticizers, PVC and pigments (dyes) are mixed together until a homogenous mix

known as

organosol is formed. The mix is the cast or measured out onto

a moving matrix called the casting sheet where it is subsequently processed

through a number of different ovens where the solvents that liquefied the mix

are evaporated. The solid film that remains is then rolled onto large cores

(kind of like the cardboard cores you see on larger 50 yard rolls of film) where

the adhesive coating is applied to one side.

Benefits of Cast Vinyl

- Due the production method used, cast films don't tend to shrink with age

- Extended life and durability due to the quality of plasticizers and raw

materials

- Available in much thinner gauges so they conform to substrates with corrugations and complex curves.

- Maintenance of color and other properties better than calendered film

- Less energy intensive process used means it's cost-effective to do small production

runs of special colors giving a wider range of colors to you.

Recommended Uses for Cast Vinyl

- Vehicle wraps

- Architectural wraps

- Smartphone (iPhone, Android) wraps

Calendered Vinyl

Calendered film is probably the most common film used by crafters and most

people are familiar with it through the ORACAL® 651 Intermediate Cal Series of craft vinyl.

The manufacturing process used to make calendered film is kind of like making

fresh pasta but with the same, noxious materials used to make cast vinyl. Sorry,

no water, semolina and eggs here — vinyl is made with straight poison. The

materials are then mixed, kneaded and expelled by an extruder like sheets of

venomous lasagna (to continue with the pasta metaphor). Finally, gargantuan,

heated steel rollers press the vinyl into thin sheets in a process called

calendering. The film gets pulled and rolled by a series of these rollers

as opposed to the casting process which uses ovens and this is one of the key

differences between the two films resulting in vastly different performance and

durability.

Benefits of Calendered Vinyl

- Stiffer and thicker for easier handling

- More economical than cast film

- Calendered films have a higher resistance to abrasion

Recommended Uses for Calendered Vinyl

- Sun Shade Visors

- Floor Graphics

- Prespaced Lettering

- Window Decals

- Wall art

- Labels

Polyester Films

Polyester films, are often marketed along side of true vinyl (PVC) films but

have different properties and performance. If you've ever worked with a metallized chrome or diamond plate film that feels

stiff and doesn't conform to curves, you've probably used a PET polyester film

without even knowing it. These films are

top coated for excellent print receptivity, and provide a

strong tear resistant surface. They're an environmentally

responsible alternative film compared to traditional

self-adhesive PVC films.

They are available in a range of colors and styles from clear to silver

to confetti as well as many other colors or tints.

Benefits of Polyester Film

- Dimensionally stable liner for easy converting

- High gloss finish

- Excellent conversion on CAD plotters

- Easy cutting & weeding

- Excellent dimensional stability

- Excellent UV, temperature, humidity, and salt-spray resistance

Recommended Uses for Calendered Vinyl

- Architectural Signage

- Directional Signage

- Window Graphics

- Emergency Vehicles

- Outdoor Advertising

- Nameplates

- Emblems

Craft and Sign Films versus Wrap Vinyl

It would be easy to draw a line between craft and sign vinyl on the one hand

and wrapping vinyls on the other simply on the basis of whether they are cast or

calendered but, as is usually the case, generalizations like that don't hold up

to scrutiny. In general, it is the case that vehicle wraps are made from cast

vinyl simply due to the fact that the casting process makes this type of film

much more durable and allows it to conform more easily to curves, corners and

crevices. And yet, as is the case with ORACAL® 8300 Transparent Calendered films

or Rwraps™ Wood Grain vinyl, there are cases when a calendered film is preferred

for wrapping.

Conversely, there are a number of cast films such as 3M™ 180mC, Avery Dennison® SC950 and ORACAL® 951 films which are primarily intended for craft

and sign use but are cast. The advantages of using premium cast films in decals,

signs, labels, etc. arte obvious in terms of improved durability and

conformability but cast films generally provide a wider color palette as well.

In fact, ORACAL® 951 Series boasts an astounding 150 different colors!

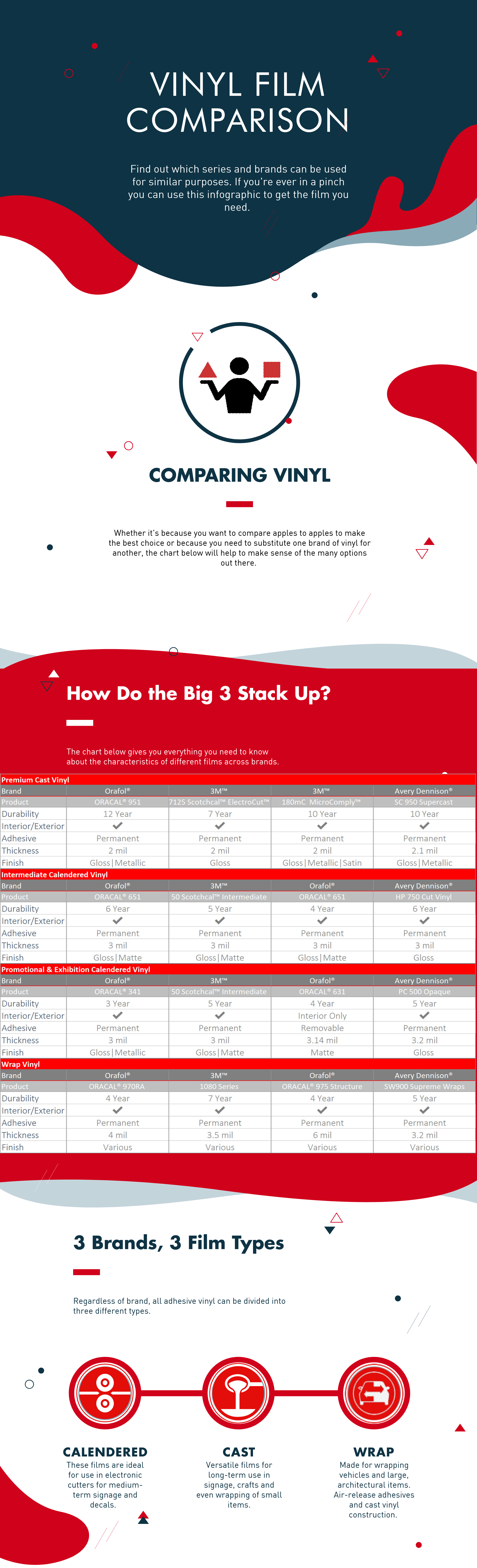

Choose Your Vinyl by Brand

Now that we've given you a brief run down of the ways to categorize vinyl

films by adhesive type, manufacturing method used and end use applications let's

take a look at all of the films we offer by brand. Bear with us though because

you're sure to be scrolling for awhile if you want to get to the bottom of this

list.

ORACAL® Films

ORAFOL, the maker of ORACAL® adhesive films, has got the craft vinyl

market on lock but they're making headway into the sign and wrapping markets too

with every year that passes. Maybe it's due to their German work ethic or maybe

just to the sheer amount of colors and films they produce but it certainly seems

like they're gunning fro 3M™.

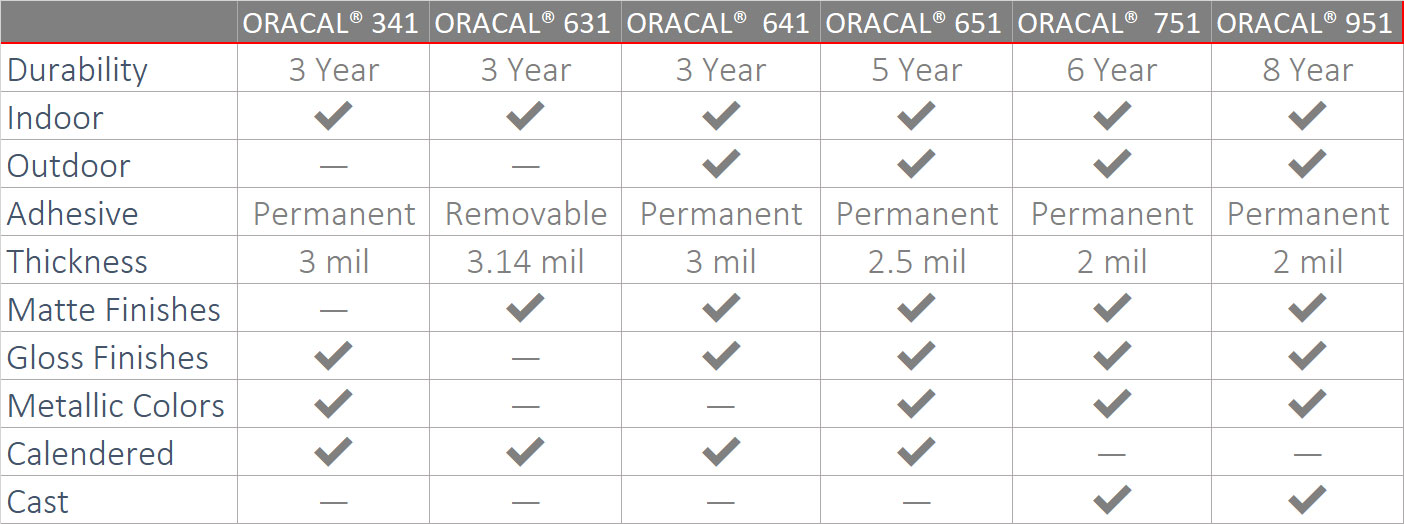

Calendered ORACAL® Films

- ORACAL® 341: Indoor vinyl available in 21 colors with up to 3 year

durability. When price is your main consideration this is the film you want.

- ORACAL® 631: This is a matte, indoor and wall-safe (removable for up to 2

years) vinyl. Made for use on walls and other indoor items that will not

be washed such as shadow boxes, picture frames, ornaments, etc. Available in

60 colors.

- ORACAL® 641: Features the same permanent solvent-based adhesive

as the 651 Series. It is outdoor safe with a 3-5 year rating. This product

can be used on hand washed items such as mugs, car windows, cups, etc.

Available in 60 colors.

- ORACAL® 651: This is the main type of adhesive vinyl that most people

end up starting with. It is a 5-8 year rated outdoor safe permanent

solvent-based-adhesive vinyl. It can also be used on items inside that you

would like to be able to hand wash such as mugs, cups, cutting boards, etc.

It comes in 61 different gloss colors plus there is a matte finish

available in white and black and a clear as well (for use as a top laminate

over some intricate designs or printed vinyl) for a total of 64 colors.

- ORACAL® 8300: This is a transparent film that is most often used for

tinting headlights and taillights but can also be used to create see-through

window decals, stained-glass effects and even to make colored chromes. Enjoy

its 5 year life and wide selection of 30 different colors.

- ORACAL® 8500: This is a translucent film that is most often used for

tinting headlights and taillights but can also be used to create see-through

window decals, stained-glass effects and even to make colored chromes. Enjoy

its 5 year life and wide selection of 30 different colors.

- ORACAL® 8510: This Etched vinyl comes in Silver and Gold in color as well as

a fine (smooth) and coarse (more textured). This product is a permanent adhesive

and gives the look of etching or sandblasting glass. This is great to use on

windows, mugs, cups, and other items that can be gently hand washed.

- ORACAL® 8710: This dusted vinyl comes in Translucent Grey. Developed for

decorative glass or mirror design elements, to achieve a translucent etched

glass appearance. Great for shop windows, room dividers and glass doors. Wet

application is recommended.

Cast ORACAL® Films

- ORACAL® 751: This is a higher-grade cast series of vinyl. More

expensive and trickier to get the hang of cutting, weeding and

applying without stretching or breaking. We carry this product in 28 colors

specifically to offer the 28 colors that do not exist in the 651 lineups.

- ORACAL® 951:This is an even higher-grade cast vinyl. It is designed to last

about 2 years longer in the sunlight than even 751 (around 8-10 years). It is

also more expensive. We carry 106 colors of this product in limited that are

not made in the 651 or 751 lines.

- ORACAL® 5600: This is a reflective permanent outdoor vinyl rated up to 7

years. It is available in 11 colors and has a clear, solvent-based, permanent

adhesive (removable with heat). This product was specifically made for vehicle

graphics that produce reflective lettering such as trailers, police cars,

ambulance, construction etc.

- ORACAL® 6510: This series is the fluorescent (neon) colors of ORACAL®

651. There are 6 colors in this series. They can be used the exact same as

651 they are not solid colored throughout, meaning that the

backside of the vinyl is not the same color as the front. For this reason, you

would not want to use 6510 where you will be looking at the bottom side of the

vinyl. This will have an outdoor lifespan of 1-2 years.

- ORACAL® 8810: Frosted vinyl is great for Long-term indoor and outdoor

decorative design; developed for long-term decorative sparkling effects on glass

and glass like shop windows and doors. It gives a similar look like the etched

vinyl but with glitter specs. Rated up to 7 years. This is available in 5

colors.

- ORACAL® 970RA & 975 Structure:

Premium dual-cast wrapping films from 4 to 6 mil thick. Available in 104

colors and styles for 970RA and 7 different finishes or patterns for 975

Structure Cast films.

- ORALUX 9300: Glow in the dark permanent adhesive vinyl. White when not

glowing and green glow in the dark. Permanent grade adhesive only available in

the one color combination(white/green). Be gentle when weeding this product, it

is a little thicker and can be more brittle.

- ORAMASK: Oramask is available in 811 and 813 are used with latex paints.

811 is a solid white color (most preferred for etching) while 813 is a

translucent blue most preferred for doing painted signs. Make sure surfaces are

very smooth before applying the stencil. Stencils are NOT reusable.

- ORALITE

- ORAJET

- ORAGUARD

3M™ Graphic, Wrap and Decorative Films

3M™ is one of the most trusted names in the world of adhesive vinyl and

,frankly, they're known worldwide for a whole lot more. When you buy a 3M™

vinyl you know it's going to be backed by the research and know-how of a company

that's second-to-none.

Cast 3M™ Films

- Controltac™ 180mC: A cast vinyl which is ideal for graphics applied to flat surfaces as well as simple and compound curves.

Perfect for hiding blemished substrates, this film also features patented

Controltac™ pressure-sensitive adhesives with Comply air-release channels

for bubble-free installations. Use it in all electronic vinyl cutters.

- Scotchcal™ 7125: This high-performance film is

available in more than 50 colors and features 7 year outdoor durability.

Specifically designed for computer cutting, this two mil vinyl also boasts

clear, pressure-sensitive adhesives.

- Scotchlite™ 680 Reflective: Retains 90% of its retro-reflectivity when wet

while resisting fuel vapors or occasional spills.

Positionable, pressure-activated adhesive for dry application only

with 9 Year Durability and 7 mil thickness.

- 1080 Series Wraps: Made for use it right out of the box

with no need to print or apply an overlaminate. Engineered with dual color layers for dimensional stability and durability, you can depend on them not to discolor or deform even around the craziest of curves. Enjoy the convenience and quality of this 3.5 mil cast film.

Yours in 9 different patterns and finishes in over 80 colors.

- Neon Series Wraps: Yours in 3 neon colors and made with

the same Controltac™ technology as premium Series 1080 wrap film. Heat-activated, pressure-sensitive wraps

with air-egress channels.

Calendered 3M™ Films

- Scotchcal™ 50: Calendered, 3 mil thick vinyl film

with a durability of 5 years. Over two dozen colors available ideal for permanent, pre-spaced, electronically cut graphics.

- Fasara Glass Decorative Films: Films apply wet and have a thickness

between 2.75 and 5.5 mil. Used for light control and privacy while enhancing

interiors. Durability of 10 years and removable without any special fluids.

- Scotchcal™ 3630 Translucent: Designed for screen printing, precut graphics and thermoforming.

Films feature a matte finish and are 2 mil thick. Use it to create the appearance of stained glass

or on glass room dividers to add a touch of privacy and color without

sacrifice light transmission or for lighted signs.

- Scotchlite™ 5100 Reflective: 7-mil, enclosed lens,

Retroreflective, engineer grade films that offer flexibility and versatility.

Available in 15 colors, including black (which reflects white).

Polyester 3M™ Films

- Scotchcal™ 7725SE Crystal: Removable, pressure-activated acrylic adhesive

with low-gloss surface and up to 10 years durability. 3.2 mil thick and

available in Frosted and Dusted varieties.

Avery Dennison® Graphics & Wrap Films

After 3M™, Avery Dennison® is probably the name that is most synonymous

with adhesives and is as much a household name and its prime rival. Enjoy their

wide selection of craft, sign, reflective and wrapping films

Cast Avery™ Films

- Avery™

PR 800 Translucent:

Cast intermediate film

with a matte finish in 15 colors. Designed for cutting plotters like Cricuts

and Silhouettes and made for easy weeding. White, poly coated liner with 6

year outdoor durability.

- Avery™ UC 900 Translucent: 51color palette

with 9 year durability.

Polyester liner

with gloss finish

for excellent conversion on vinyl cutters.

- Avery™

SC 950:

Available in Opaque, Metallic and Ultrametallic finishes, this

Super Cast 950 film is the Cadillac of craft and sign films.

- Avery™ SF 100 Conform Chrome: Yours in 5 bold, mirror chrome colors. 53 inches

in width and sold by the foot.

3 year durability

90# StaFlat™, poly-coated with liner Avery™ Easy Apply™ RS technology

and 5.7 mil thickness for ease of installation.

- Avery™ SF 100 Fluorescent: 6 bold, fluorescent colors

in a 53 inch wide format.

Up to 6 month durability

with Avery™ Easy Apply™ RS technology

and 2.2 mil thickness.

- Avery™ SF 100

Glow-In-the-Dark:

Green,

glow-in-the-dark

and 48 inches wide.

5 year indoor durability and 6 mil in thickness. Ideal for flat, simple curved

surfaces.

- Avery™ SW 900 Series Supreme Wrapping: Dual layered vinyl film

available in 12 styles: Gloss, Gloss Metallic, Matte, Matte Metallic, Carbon Fiber, Brushed, ColorFlow, Chrome, Diamond, Extreme Texture, Satin

and Pearl.

Pressure-sensitive adhesives

with air-release channels for bubble-free results.

Semi-permanent and removable.

Calendered Avery™ Films

- Avery™ HV 1200

Reflective:

A 4.5 mil film with

7 year durability. Featuring a clear, permanent acrylic adhesive.

- Avery™ HP 750 Opaque:

Patented Advanced Acrylic Adhesive Technology (PAAAT) enhances shelf life

and makes weeding easy. Featuring a high-gloss finish

with great UV, temperature, humidity and salt spray performance.

Pantone color reference makes design easy with this 6

year rated, 3 mil thick film.

- Avery™ PC 500 Opaque Calendered: Easy transferring for signage and graphics

with 4 year durability. Dimensionally stable liner and 3.2 mil thickness. Made especially for use on CAD plotters and computer cutters

like Cricut, Silhouette.

Polyester Avery Dennison® Films

- Avery™ SF 100 Metalized: These metallized polyester

films are 24 inch wide with 3 year durability. 4 mil in thickness

and available in 9 styles. Acrylic-base, pressure-sensitive

adhesives for flat surfaces and use in vinyl cutters.

In a Pinch? This Vinyl Comparison Infographic Should Help

Rvinyl Brand Rwraps™ & Rtint™ Films

Because we offer over 100 different types of film in every category it would

be impossible to split them up into the groupings of cast, calendered and

polyester films we've used in the preceding sections. We hope that you won't be

overwhelmed by the information and encourage you to contact us if you have any

questions.

- Rwraps™ Brushed Aluminum: Available in a number of

colors, all of these 3 mil thick films are cast and feature a true,

three-dimensional grain running along the length of the film. Air-drain

adhesives and available in 12, 24 or 60 inch widths.

- Rwraps™ Camouflage: 21 great camo patterns available. 3

mil thick with air-drain adhesives. 12, 24 and 60 inch widths available.

- Rwraps™ Carbon Fiber: 3D and 4D finishes and available

in colored and chameleon versions. Featuring air-release adhesives, this 3

mil film is also available in 12, 24 and 60 inch wide formats.

- Rwraps™ Chameleon: Sparkling, shade-shifting films.

3 mil thick with air-drain adhesives. 12, 24 and 60 inch widths available.

- Rwraps™ Chrome: 7 colors available. 1 year durability.

3 mil thick with air-drain adhesives. 12, 24 and 60 inch widths available.

- Rwraps™ Colored: Dozens of colors available. 2 mil

thick. Most films available in 60 inch widths but also 12 and 24 inches.

- Rwraps™ Diamond Plate: Polyester film with a chrome

finish and realistic holographic diamond plate. 2 mil thick and clear,

acrylic adhesives.

- Rwraps™ Engine Turn: Polyester film with a chrome

finish and realistic holographic turned metal look. 2 mil thick and clear,

acrylic adhesives.

- Rwraps™ Galaxy: Three styles of deep space-themed cast

wrapping vinyl. 3 mil with air-release channels. Yours in 12, 24 and 60 inch

widths.

- Rwraps™ Lightning: Choose either White or Blue. Cast, 3

mil thick with air-drain adhesives. 12, 24 and 60 inch widths available.

- Rwraps™ Leather: Cast film with real leather texture in

two colors. With air-release adhesives, this 3 mil film is also available in

12, 24 and 60 inch wide formats.

- Rwraps™ Matte: Dozens of colors available. 2 mil thick.

Most films available in 60 inch widths but also 12 and 24 inches.

- Rwraps™ Matte Chrome: 8 colors of with a satin finish

and a metallic flake. Cast, 3 mil thick with air-release adhesives and

available in 12, 24 and 60 inch wide formats.

- Rshield™ Protection: 2 mil thick, clear calendered

film. Choose from 12, 24 or 60 inch wide rolls or sheets.

- Rwraps™ Rust: 3 styles available. 3 year durability. 3

mil thick with air-drain adhesives. 12, 24 and 60 inch widths available.

- Rtint™ Smoke: Calendered, transparent film in 14

colors. 2 mil thick with 3 year durability.

- Rwraps™ Snake Skin: Realistic, three-dimensional scale

patterns in Black or White. Cast, 3 mil thick with air-drain adhesives. 12,

24 and 60 inch widths available.

- Rwraps™ Sticker Bomb: High-gloss, sticker bomb patterns

in 6 styles. 3 mil thick, dual-cast film with air-release adhesives.

- Rtint™ Window Tint: Single ply window tint film

available in 5, 20, 35 and 50% VLT.

- Rwraps™ Wood Grain: Calendered wood grain films with

real texture in both matte and gloss finishes. Perfect for wraps and cutting

in Cricut and Silhouette machines.

Get the Film You Need Today

So you've made it to the end of the article and still don't know

what you need, have you? Well, luckily for you, we're here to help.

Simply chat with us during business hours or drop us a line by email

and we will be happy to help you pick out the right type of vinyl

for you.