Vinyl Wrap Tips - Cold Pre-Stret

Vinyl Wrap Tricks - Heat Gun Techniques

The heat gun: as much as DIY installers hate to admit it is the one vinyl

wrap tool you just can't live without. As we mentioned in our post on

cold pre-stretching, vinyl films have

a memory which is both a curse and a blessing. Most importantly of course though is

the fact that this memory can only be triggered through the use of a heat gun.

Today we'll cover four different heat shrinking techniques that anyone can

perform with a heat gun and that will take your wrapping expertise into the big

leagues and give you pro-grade results.

Tension is the Key

When you're wrapping a large area of a vehicle you want to anchor the film to

about four points (depending on the application and assuming that your wrap is

rectangular). As you do this, you want to tension the film trying to make it as

smooth and as taught as possible. When you've got the film in position as tight

as you can you will notice some larger ripples or wrinkles in the vinyl. This is

completely normal. Spend a couple of minutes going around and actually adjusting it trying to remove as many of these wrinkles

and ripples as you can out of the film.

Chasing Wrinkles

At this point, once the film has been tensioned and smoothed as much as

possible, it's time to use some heat on those remaining wrinkles to activate the

vinyl's memory. In essence, vinyl wrap films behave exactly like shrink-wrap

when heated. Of course, it take a little practice to know how much heat to use

and how much you can stretch a given film but with some time and patience you'll

be a pro in no time.

Naturally, there are some parts of the wrap where the heat gun technique won't work. There's only a certain amount that the

film will actually shrink so you'll find that there are some parts where there's

a curvature in the panels that results in an excess amount of intentioned film

so it can't shrink. Typically those areas are near the edge of the panels anyway so they can

be dealt with later using another technique. At this point, it's really now just a matter of

using your squeegee and basically just pushing the film straight onto the

surface of the smoother areas you've already shrunk.

Removing Small, Tight Ripples

Certain areas of every vehicle cause special issues. Some prime examples of

this are badges, door handles and gas caps which can create areas of highly

localized tension which results in tight, small ripples. In order to prevent

these from becoming larger wrinkles and eventually much dreaded creases, it's

best to remove them early on. How to do it?

Since today's post is all about heat gun techniques, of course you need to

use your heat gun. Apply heat along with a squeegee or application card to

smooth out and push in the sharp ripples. In another post we'll get into how to

approach door handle and gas cap wraps but for the time being this is all you

need to know to wrap the larger areas of your car, truck ort SUV.

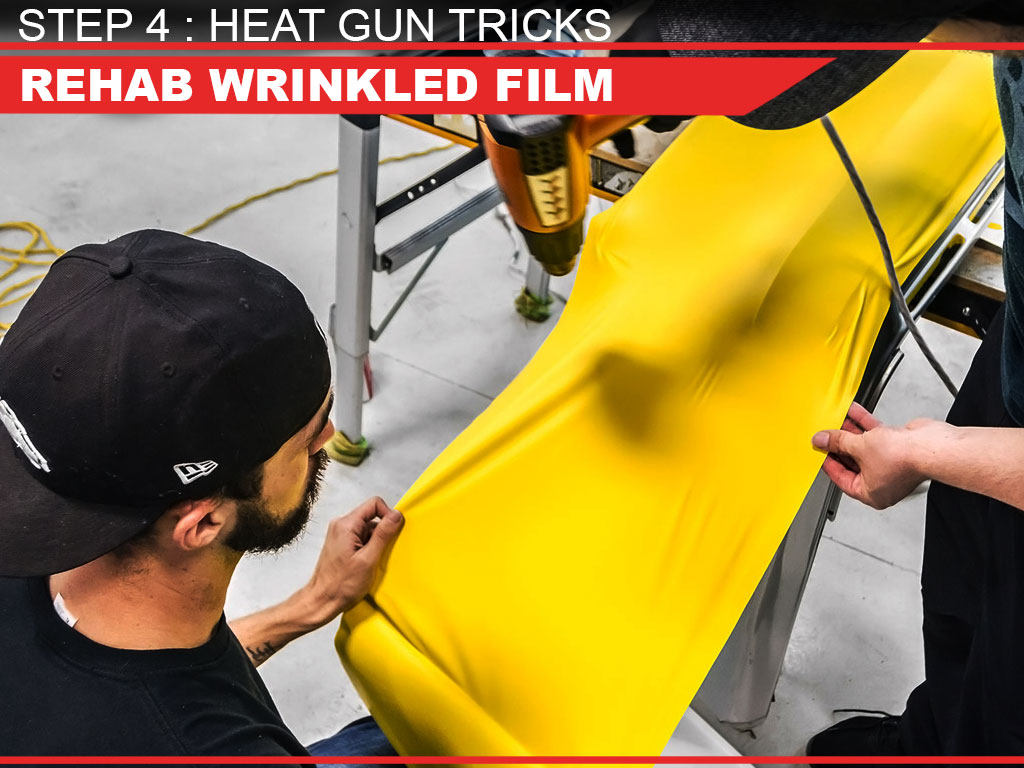

Putting Vinyl Memory to the Test

Once you've worked out all of the major wrinkles and tiny ripples using the

techniques above, there's a good chance you'll have some pretty gnarly and

wrinkled vinyl at the edges. Here too, your heat gun will save the day and help

you salvage the film. Simply hold the vinyl taught and use the same technique to

release and shrink the vinyl wrap back into its smooth shape. Easy as pie.

Obviously, seeing these things done is much easier than reading about them,

so we've included two videos below from 3M™ that show how to work with a heat

gun and which cover all of the tips above. We're constantly adding new

installations of our Wrap Tricks series so be sure to check back soon.