Vinyl Wrap Tips - Cold Pre-Stret

Vinyl Wrap Tips - Cold Pre-Stretch Technique

Vinyl Wrap Tips - Cold Pre-Stretch Technique

In 2009, a group of German vinyl wrap installers discovered the pre-stretch technique and it revolutionized how installers wrapped difficult areas such as mirrors and bumpers. The only drawback to the pre-stretch technique is it only works gloss, matte and gloss/matte metallic films.

At present, textured films like Brushed Metallic, Carbon Fiber and multi-layered films

like as Chrome, the film distorts or whitens when the technique is

applied. As good as pre-stretch is, it's limited.

One of the most frustrating things about wrapping anything with vinyl films

is that they have a tendency to "shrink back" after having been installed on

curved, convex and concave surfaces. According to Justin Pate of the Wrap

Institute, all PVC film has a memory which means that it will tend to return to

its size. In other words, when you heat PVC film it goes back to its original

shape and tension. Clearly this is a double edged sword. Why is that? Well,

imagine the scenario below and you might get a better idea.

When a Good Memory Is Great

You've just received a roll of 3M™ Matte Red Metallic film. If you're a DIY

installer or amateur you might not be familiar with the film and how thin it is.

As a result, it folds in upon itself as soon as you remove the paper liner. Now,

luckily for you, 3M™ 1080 Series films feature Controltac™ adhesives for a

low-tack initial bond so you're able to flatten it all out again. But, once you

have the results aren't pretty — that is, until you add some heat! As soon as

you do, the ripples and dimples vanish as the vinyl wrap film returns to its

former shape thanks to its memory. So, memory is a great thing, right? Well, not

always.

When Amnesia Might Be Better

There are some cases where you'd rather your wrapping vinyl have a case of

amnesia. Prime examples of this are when you find yourself trying to wrap a

mirror, your hood or anything with more than a 180-degree angle. You see, most

of us do-it-yourselfers, can wrap anything pretty quickly. Sure, getting the

fingers out when you're wrapping an extreme curve can be a little time consuming

but we've all been there and succeeded. Unfortunately, those moments of victory

are usually extremely short-lived. A vinyl wrap that looked good one day one

starts to look less spectacular on day two until the film has finally retreated

up to a quarter of an inch from the edge of whatever it's supposed to be

covering. And why? Memory.

Cold Pre-Stretching — A Miracle Solution to Vinyl Memory

According to Justin Pate, a Japanese installer named Koji Yamaguchi taught

him the cold pre-stretch technique while wrapping a door handle that he,

himself, had learned eight years previously in Germany. In essence, in order to

pre-stretch the material you heat it and then stretch it to about 2 to 4 percent.

You then allow it to return to its normal size. At present this technique only

works with gloss and matte films but it's a life-saver nonetheless

Sounds simple, right? Clearly we've glossed over a lot of the details which

is why we'll present the video in its entirety below. But, in case you're a list

lover, we've included the steps you need when wrapping a curved surface like a

rear view mirror:

- Begin on the back side of the rear view mirror sinc eit has the steepest

angle.

- Anchor the film and ensure that there is an equal amount on either side

of the mirror's face.

- Use Justin Pate's "triangle technique" and pul firmly in order to

stretch the film onto the surface to be wrapped.

- Even out the tension with your fingers.

- Once evenly distributed on the mirror, keep the stretched material

(stretched from 2 to 4%) about an inch from the edge.

- If doen correctly, the wrinkles at the edges will be very loose and soft

instead of tight and sharp.

- When the excess is cut away the, the wrap will stay for years.

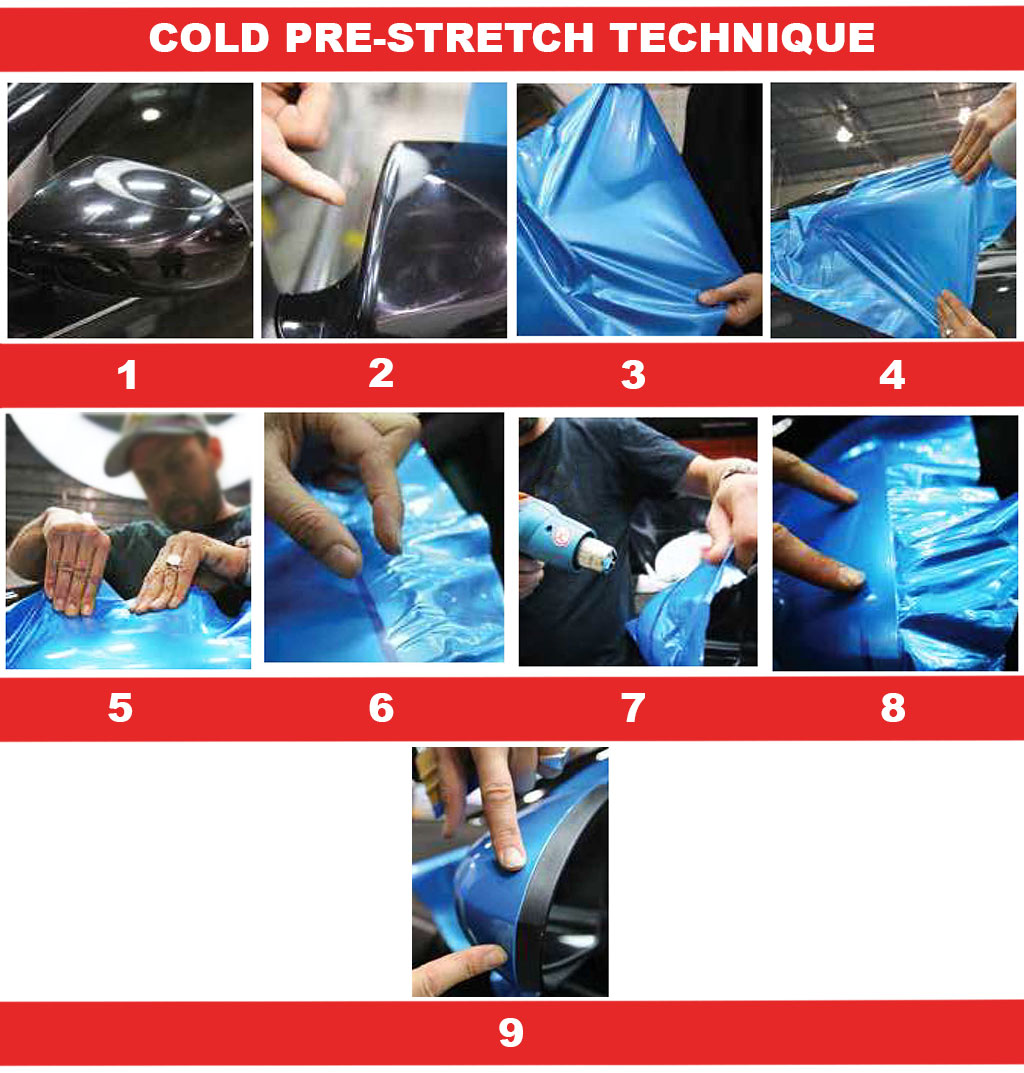

Here are the step by step pics to help you see exactly how it's done:

And, finally, here's the

video for your viewing

pleasure.