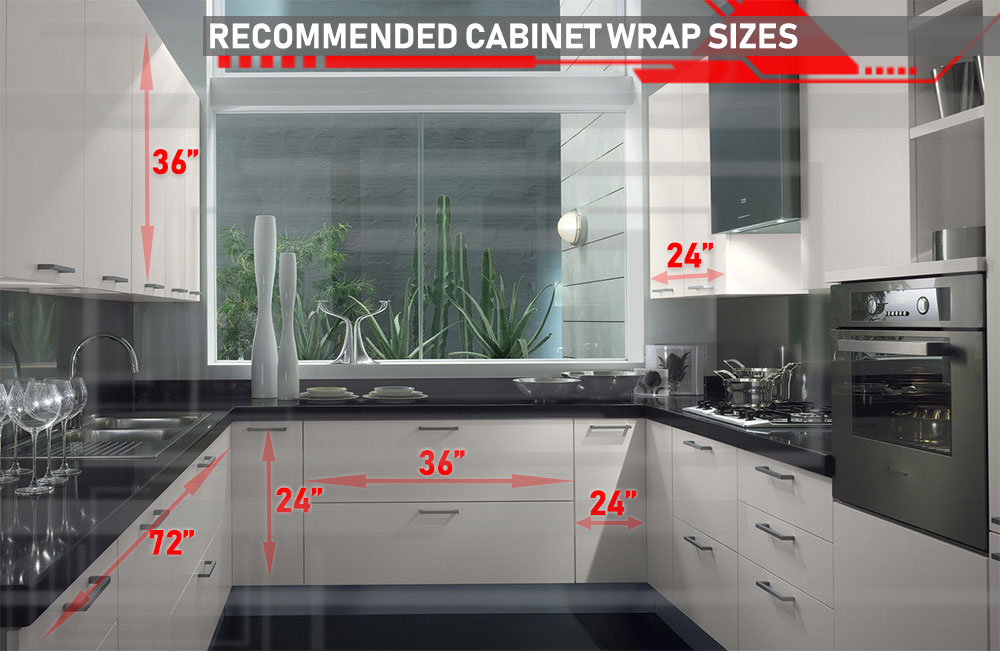

Cabinet Refacing with Wood Grain Wraps

You've decided to update the look of your dirty, aging cabinets and, since

you're not a self-made millionaire you won't be swinging by Home Depot to pick

up a full set of replacement cabinets for your kitchen in bath. Instead,

somebody told you how you can reface your cabinetry with peel-and-stick

woodgrain vinyl and you've either bought it online from a site like ours or

found it locally. Now that you have your roll of precut sheets of wood grain

wraps, you just need to figure out how to apply it and be the home improvement

hero your family needs!

Cabinet & Furniture Wrap Supplies

We recommend the following

supplies and tools to make your wrapping experience as flawless as possible:

- A sheet of the wood grain vinyl you want to use to reface your cabinets

- An Olfa-style Exacto knife

- Heat gun

(optional)

- Squeegee

- Sanding block

2500 grit sandpaper

Step 1: Clean and Prepare

Before applying the vinyl wrap to the target surface, make sure your

surface is clean. Use a general cleaner to remove surface contaminants

that may hinder adhesion.

If your surface is uneven, chipped, peeling or generally in questionable

condition, sand or scrape off anything that will create an undesirable

impression or look.

Once surface is dry, measure your piece of vinyl and cut to desired

shape (make sure you leave a 2-inch excess on all sides for easier

handling).

Lastly, peel the Rwraps™ liner backing from the vinyl and

place the film into it's desired position.

Using a flat edge or squeegee, use moderate pressure starting from the

middle - outwards and push any trapped air to the edges of your panel

until expelled. Using a heat gun and light pressure, seal the vinyl into

place.

Step 2: Cut Corners and Edges

Using a sharp blade, slit the corner of the panel at a 45-degree angle. This is the first step in making clean edges.

Step 3: Cut Corners and Edges Continued

Fold the edge onto the adjacent side for easier

detailing.

Using a sharp blade, trim the excess film

leaving a 3 to 5 mm wrap around the edge. This

seam will allow for a long-term application

without the chances of peeling.

Step 4: Under-fold and Cut Away Excess Vinyl

Apply the film over the "under-fold" and align the excess for

a clean trim.

By holding the tip of the excess, carefully cut the excess from

the corner edge for a seamless look.

Step 5: Seal Edges

Once the corner is flush, heat, press and seal the vinyl into place.

Step 5: (Optional) Sanding Edges

As a final, and completely optional step, you may gently rub the seam on the corner with medium or fine-grit sandpaper so that no edge can be felt. But don't overdo it as you can cause the film to peel. As a finishing touch you can also use a Seal-It pen to seal any seams.